Barrier Films

The barrier films developed by PROCHIMIR are based on polyolefins, TPU, CoPES or CoPA.

They provide barrier properties against industrial or body fluids and water. They also protect against dust, puncture or bumps, play an active role in noise or light insulation.

By controlling the surface tension, the PROCHIMIR barrier films can be printed, foamed, coated or even aluminized.

HF weldable, the TPU films are also a chlorine- and phthalate-free alternative to PVC for inflatables (bladders, inflates, balloons, vessels).

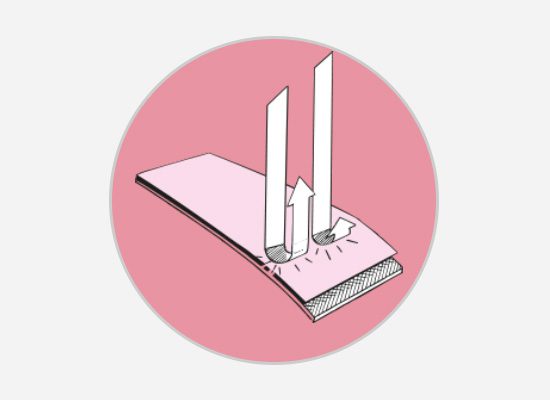

The barrier films may be coextruded to add them one or two layers of adhesives. These engineered structures are to be applied, either on top of a surface or incorporated into a composite structure.

Beyond a customized geometry, PROCHIMIR proposes multiple options : Corona treatment, Colors, Surface finishing, Fire retardancy, Skin contact, UV resistance, FDA agreement…

Barrier Films Multilayer

| Reference | Nature | Adhesive melting range (°C) | Barrier melting range (°C) | Fluidity (adhesive layer) | Washing resistance (°C) | Dry cleaning resistance | Plasticizers resistance | Hydrolysis resistance |

Minimum thickness (µm) |

Structure* | Comments | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Polyolefins | TC 1027 CX 00 | EVA/PE | 75-85 | 120-130 | High | – | – | – | + | 25 | A/B – A/B/A | Low melting EVA film with PE barrier |

| TC 1500 CX 01 | PE/PE | 100-105 | 120-130 | Medium | 60 | – | – | + | 25 | A/B – A/B/A | General purpose multilayer PE film |

|

| TC 1600 CX 80 | PE/CoPA | 100-120 | 210-220 | Low | 60 | – | – | + | 60 | A/B/A | High temperature multilayer film for thermocompression |

|

| TC 1600 CX 92 | PE/PP | 105-110 | 160-170 | Low | 60 | – | – | + | 30 | A/B – A/B/A | Multilayer film with good elongation properties |

|

| TC 3300 CX 18 | EVA/PP | 80-90 | 160-170 | Medium | 60 | – | – | + | 60 | A/B | Bilayer film with good resistance to industrial fluids |

|

| TC 3300 CX 70 | PP/PP | 130-140 | 160-170 | Medium | 60 | – | – | + | 30 | A/B – A/B/A | High temperature multilayer film with good resistance to industrial fluids |

|

| TC 5125 CX 18 | EVA/TPU | 80-90 | 160-175 | Medium | 60 | – | – | – | 25 | A/B – A/B/A | Strong EVA adhesive with high temperature TPU barrier |

|

| TPU | TC 5025 CX 03 | TPU/TPU | 70-85 | 160-180 | Medium | 30 | – | – | – | 20 | A/B – A/B/S | Bilayer TPU film for foam covering |

| TC 5020 CX 11 | TPU/TPU | 115-125 | 145-155 | Medium | 60 | + | – | – | 40 | A/B/A | Trilayer TPU film | |

| TC 5563 CX 11 | TPU/TPU | 115-125 | 180-185 | Medium | 60 | + | – | – | 20 | A/B | Bilayer TPU film with high chemical resistant Ether barrier |

|

| TC 4070 CX 20 | TPU/CoPES | 145-155 | 215-225 | Medium | 60 | + | – | – | 35 | A/B – A/B/A | TPU adhesive with a stable CoPES barrier up to 200°C |

|

| CoPA | TC 203 CX 176 | CoPA/PE | 115-130 | 110-120 | High/Low | 60 | – | + | + | 25 | A/A | Specific film to bond ABS / PC and PA on other substrates |

| TC 5526 CX 205 | CoPA/TPU | 120-130 | 165-170 | High | 60 | + | + | + | 25 | A/B | Bilayer film combining a strong adhesive and a high chemical resistant barrier |

* A : Adhesive B : Barrier S : PE Carrier

Technologies to apply our barrier films

Coating Technologies

Die Cutting - Punching

Flame lamination

Injection Molding

-

Cannon

-

Hennecke

-

Krauss Maffei

-

OMS Group